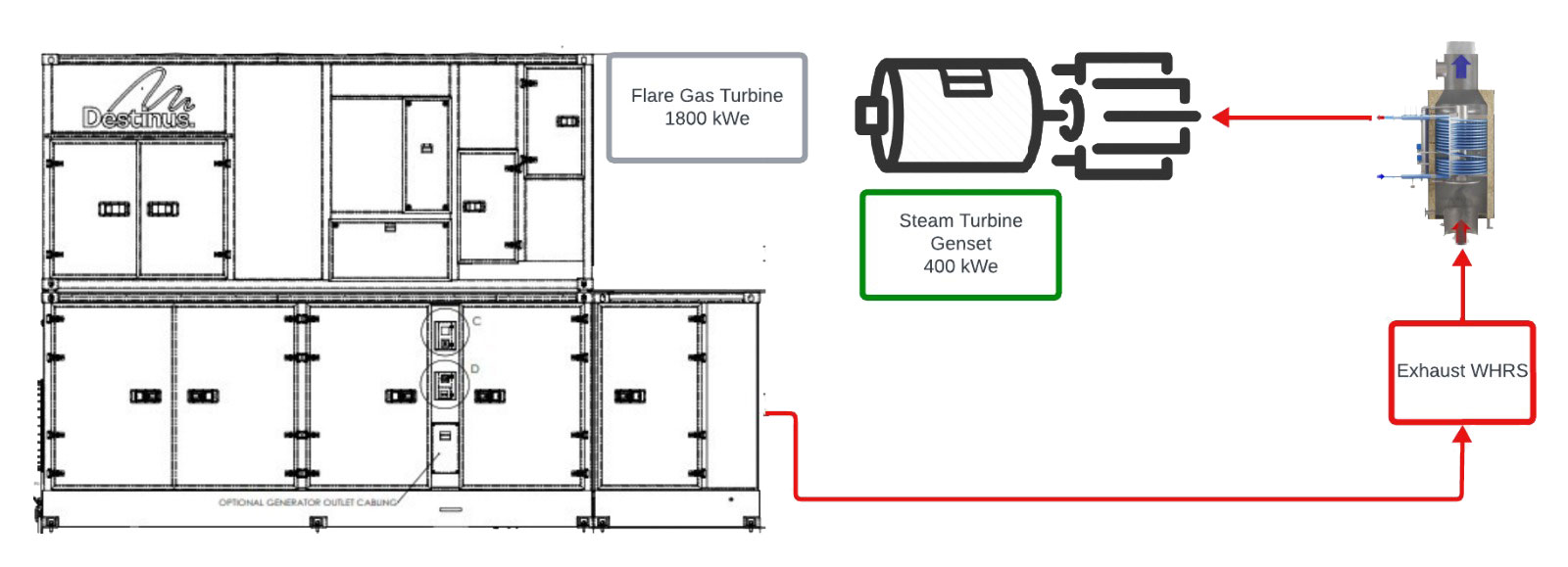

Waste Heat Recovery is a compact exhaust gas heat exchanger specially designed for waste heat recovery from small gas turbines, engines, and clean process flue gas. It can also be used as an economizer or condensing economizer for gas or diesel-fired boilers. Featuring a durable design, Waste Heat Recovery has a heating surface consisting of a series of coaxial tubes arranged in a vertical or horizontal cylindrical shell plate. This ensures long-term, trouble-free performance and offers capacities ranging from approximately 250 to 5000 kW. Waste Heat Recovery can effectively operate with a variety of media, including water, steam, triethylene glycol (TEG), and thermal fluid oil (TFO). Maintenance-friendly, this heat exchanger can be cleaned either through a pyrolysis process when installed in dry-run mode or by using optional soot blower rings with compressed air, steam, or water. When necessary, an integrated regulation damper allows a portion of the exhaust gas to bypass the unit’s heating surface.